Microwave digestion technology uses the penetrating and reactive activation capabilities of microwaves to heat reagents and samples in sealed containers, which can increase the pressure in the sample preparation container and raise the reaction temperature, thereby greatly increasing the reaction rate and shortening the sample preparation time.

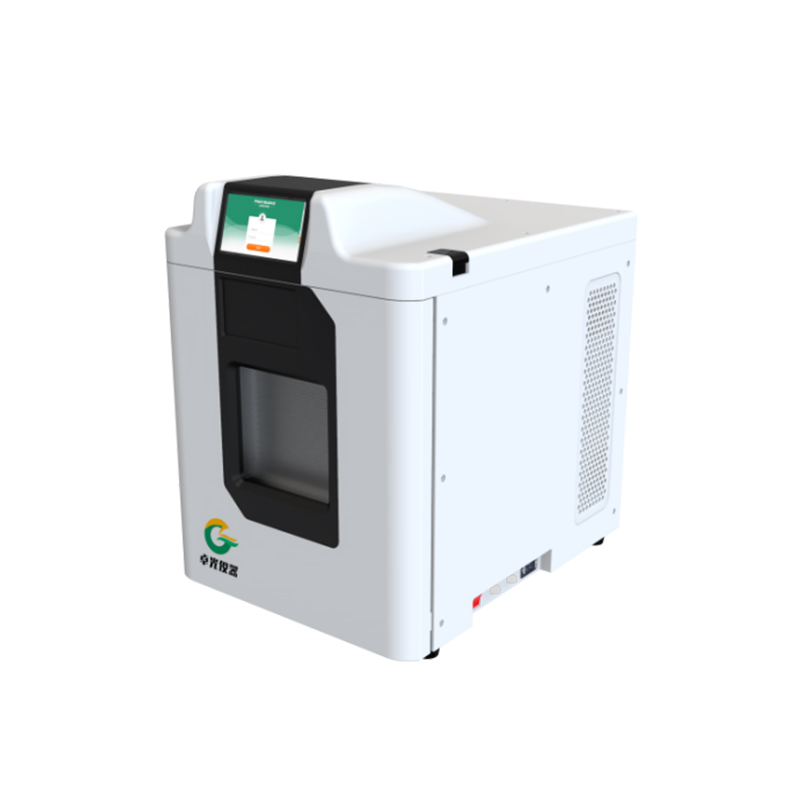

Product Description

Our Microwave Digestion Systems are state-of-the-art analytical tools that have been developed to meet the demanding requirements of modern sample digestion. These systems utilize the unique properties of microwave energy to provide a highly effective and efficient method for breaking down samples.

The microwave source in our systems is carefully calibrated to emit a stable and uniform microwave field within the digestion chamber. This ensures that all samples placed in the chamber are heated evenly and rapidly. The digestion vessels are constructed from premium materials that offer excellent chemical resistance and thermal stability. They are designed to fit snugly within the chamber, maximizing the interaction between the microwave energy and the samples.

The control panel of our Microwave Digestion Systems is user-friendly and intuitive. It allows users to set up and initiate digestion programs with ease. The system provides real-time feedback on the progress of the digestion, including temperature, pressure, and time remaining. Users can also make adjustments to the program parameters during the digestion process if necessary.

Key Features

1. Rapid Sample Preparation: One of the main advantages of our Microwave Digestion Systems is the rapid sample preparation time. Compared to traditional digestion methods, our systems can reduce the digestion time by up to 90%. This not only saves time but also allows for a higher sample throughput, increasing the productivity of the laboratory.

2. Low Blank Values: Our Microwave Digestion Systems are designed to minimize the introduction of contaminants during the digestion process. The use of high-quality materials and the controlled environment within the digestion chamber result in low blank values. This is crucial for accurate trace element analysis, as it reduces the interference from background contaminants.

3. Remote Control and Monitoring: Our Microwave Digestion Systems can be controlled and monitored remotely through a computer or a mobile device. This feature provides users with the flexibility to start, stop, and adjust the digestion process from a distance. It also allows for real-time monitoring of the digestion progress, enabling users to respond quickly to any changes or issues that may arise.

4. Automatic Calibration: The systems are equipped with an automatic calibration function that ensures the accuracy and reliability of the temperature and pressure measurements. This function regularly checks and adjusts the sensors to maintain their performance over time. The automatic calibration feature reduces the need for manual calibration, saving time and ensuring consistent results.

5. Expandable Capacity: Our Microwave Digestion Systems are available in different models with varying capacities. Users can choose the model that best suits their needs, whether they require a small system for occasional use or a larger system for high-volume sample processing. Additionally, the systems can be easily upgraded or expanded in the future to accommodate increasing sample volumes.

Applications

1. Nuclear Industry: In the nuclear industry, our Microwave Digestion Systems are used for the analysis of radioactive samples. They can be used to digest uranium ores, nuclear fuels, and radioactive waste for the determination of their elemental composition and radioactivity levels. The rapid and efficient digestion process is essential for handling radioactive materials safely and accurately.

2. Textile and Leather Industry: The textile and leather industry uses our Microwave Digestion Systems for the analysis of dyes, pigments, and other chemicals used in the production process. These systems can be used to determine the chemical composition, purity, and quality of these substances, ensuring that the final products meet the required standards.

3. Automotive and Aerospace Industry: In the automotive and aerospace industries, our Microwave Digestion Systems are used for the analysis of materials such as metals, alloys, and composites. They can be used to determine the elemental composition, mechanical properties, and corrosion resistance of these materials, which is crucial for the design and development of high-performance components.

4. Research and Development in Chemistry: Our Microwave Digestion Systems are widely used in research and development laboratories in the field of chemistry. They are used for the preparation of samples for a variety of analytical techniques, such as atomic absorption spectroscopy, inductively coupled plasma mass spectrometry, and high-performance liquid chromatography. The systems provide a reliable and efficient method for sample digestion, enabling researchers to obtain accurate and reproducible results.

Power supply | 220-240 VAC 50/60Hz 15A |

Microwave source | 2450 MHz, dual magnetron high-energy microwave field emission. |

Installation power of the whole machine | 3200W |

Maximum microwave output power | 2200W, microwave non-pulse continuous automatic frequency conversion control. |

Display screen: | Large 7-inch touch LCD screen. |

Software system: | The ARM chip comes with a ZG operating system. |

Microwave cavity | 65L, large volume 316L stainless steel cavity, internal and outer multi-layer corrosion resistant PFA Teflon spraying. |

Temperature-control system | Real-time detection and control and display the temperature and curve in all reaction tanks, inside dissolving tank: maximum temperature ≥300C. |

Safety and explosion-proof door design | Eight-layer steel structure self-pop-out explosion-proof buffer design (AUT-relief structure), electronic and mechanical dual safety protection. |

* Pressure control system | The pressure control system G-pressure monitors all reaction tank pressure in real time, over pressure automatically adjust / stop microwave emission and automatic alarm. |

Pressure-measuring system | Piezoelectric pressure sensor, display accuracy: ±0.1MPa, external tank of the digestion tank: withstand pressure ≥ 20MPa, inner tank of the digestion tank: maximum pressure ≥ 4MPa, volume ≥100 mL. |

* Temperature measurement system | High-precision optical fiber temperature sensor, temperature measurement range: -50-350℃, control accuracy ± 0.1℃, display accuracy ± 1℃. |

* Video surveillance system | It can monitor the operation situation of the digestion tank in the furnace chamber in real time through the internal camera (optional). |

Full-tank temperature monitoring system | Full temperature monitoring, temperature range: 0-350℃, control accuracy ± 0.1℃. |

Full-tank pressure passive protection system | Using the top safety pressure relief device (security) design, over pressure quantitative directional automatic pressure relief. |

External network interface (optional) | USB, RS-232 |

Sample reaction external tank | PEEK material explosion-proof external tank. |

Furnace exhaust system | High power corrosion resistant axial flow fan, turbulent and efficient air cooling, the time to decrease temperature from 200℃ to 60℃ is only 15 minutes. |

Working environment temperature / humidity | 0-40 °C / 15-80% RH |

Net weight and dimensions of the whole machine | 580 * 680 * 720mm (width * depth * height), 65 KG |

* Name of reaction tank | 6 tanks with high pressure resistance |

Model of reaction tank | ZG 06 |

* Batch amount | 6 |

Material of inner tank | TFM |

* Material of explosion-proof external tank | PEEK |

Digesting rotor frame structure | High strength turntable integrated frame |

Reaction tank volume | 100ml |

Temperature measurement mode | Inserted type high-precision optical fiber temperature sensing and bottom infrared temperature scanning, dual temperature control temperature measurement. |

Why Choose US

Shanghai Zhuoguang Instrument Technology Co., Ltd. focuses on the scientific instrument industry, manufacturing high-quality instruments and providing perfect services. Committed to innovation in the fields of food and drug analysis and testing, promoting "green food" and "healthy drugs", providing high-quality laboratory instruments and equipment, technical services, and integrated solutions for food safety, environmental monitoring, biochemical research, pharmaceuticals, petroleum industry, new material research, etc.

The company currently has instruments and equipment such as fully automatic potentiometric titrator, microwave digestion analyzer, fully automatic polarimeter, fully automatic video melting point apparatus, fully automatic grease melting point tester, fully automatic refractometer, calorimeter, densitometer, UV/visible spectrophotometer, fully automatic Karl Fischer moisture meter, etc.

We Independently researched and developed, obtained multiple invention patents, and we are a national high-tech enterprise.

We provide high quality after-sales service, with a dedicated after-sales team to ensure timely resolution of customer issues.

We are manufacturer that offer competitive prices to achieve mutual benefit and win-win outcomes.

We manufacture high-quality products to ensure an excellent user experience.

We have various qualification certificates, such as ISO9001, CE certificates, patent certificates, and software copyright certificates.

We can customize products according to customer needs to meet their local requirements.