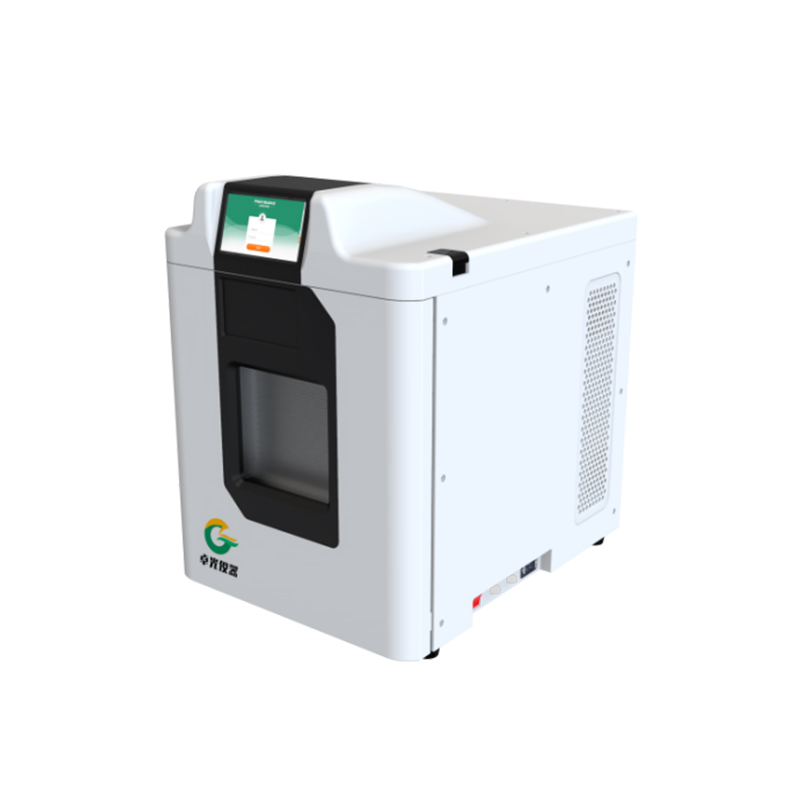

Testing refractive index nD, average dispersion (nF nC) of liquids or solids and the mass fraction (known as Brix) of dry solids in sugar solution.

Application for detection and analysis in sugar, pharmaceutical, beverage, petroleum, food, chemical industry production, scientific researchand teaching departments.

1: Support network printing and data statistical retrieval;

2: LED cold light source instead of traditional sodium lamp and halogen tungsten lamp;

3: 7-inch touch color screen, humanized operation interface;

4: Compliant with 21CFR Part 11 audit trail, pharmacopoeia and electronic signature, compliant with pharmacopoeia FDA functionality;

1: Built-in Peltier temperature control, improve accuracy and stability;

2: LED cold light source instead of traditional sodium lamp and halogen tungsten lamp;

3: 7-inch touch color screen, humanized operation interface;

4: Compliant with 21CFR Part 11 audit trail, pharmacopoeia and electronic signature, compliant with pharmacopoeia FDA functionality;

1.Contains 2-channel liquid adding module, standard 16 stations, optional 20/34/40 station turntable auto sampler.

2.Can drive multiple liquid adding module units, burettes and pipelines should be acid, alkali and corrosion resistant.

3.Imported corrosion-resistant polytetrafluoroethylene rotary valve, PTFE corrosion-resistant burette, high-power stirring table, coil for magnetic stirring.

4.High-precision closed-loop control to ensure accurate titration.

1: Improve precision and stability;

2: LED cold light source instead of traditional sodium lamp and halogen tungsten lamp;

3: 7-inch touch color screen, humanized operation interface;

4: The whole machine has passed the TART and CE certification;

1: Automatic integration to realize one-button measurement function;

2: Treat 4 samples at a time;

3: HD video instead of the traditional microscope, high visual inspection;

4: Meet 21CFR Part 11, audit tracking, pharmacopoeia and electronic signature;

1: Automatic integration to realize one-button measurement function;

2: Treat 4 samples at a time;

3: HD video instead of the traditional microscope, high visual inspection;

4: Automatic recording of melting process, initial melting, final melting;

The GP90 Polarimeter features built-in Peltier temperature control for enhanced accuracy and stability, along with an energy-efficient LED cold light source, replacing traditional sodium and halogen tungsten lamps. It complies with 21CFR Part 11 audit tracking, meets Pharmacopoeia 2020, and adheres to cGMP/GLP requirements with electronic signature functionality. With a working wavelength range of 589.3nm/546nm/405nm/365nm (optional), it offers flexibility for various applications in industries like pharmaceuticals, food, and chemicals. The GP90 ensures precise optical rotation measurements, making it an essential tool for quality control and research in regulated environments.

1: Built-in Peltier temperature control, improve accuracy and stability;

2: LED cold light source instead of the traditional sodium lamp and halogen tungsten lamp;

3: Compliance with 21CFR Part 11 audit tracking, comply with Pharmacopoeia 2020 and electronic signature;

1: Built-in Peltier temperature control, improve accuracy and stability;

2: LED cold light source instead of the traditional sodium lamp and halogen tungsten lamp;

3: Compliance with 21CFR Part 11 audit tracking, comply with Pharmacopoeia 2020 and electronic signature;

The GP60 Fully Automatic Polarimeter is designed for precise determination of optical rotation, specific rotation, concentration, sugar degree, and custom parameters. Equipped with built-in Peltier temperature control, it ensures improved accuracy and stability. The advanced LED cold light source replaces traditional sodium and halogen tungsten lamps, offering better energy efficiency and longer lifespan. Compliant with 21CFR Part 11 audit tracking and the 2020 Pharmacopoeia, it ensures regulatory adherence with secure electronic signatures. Ideal for use in pharmaceuticals, food, chemicals, and research, the GP60 delivers reliable, high-precision measurements across various industries.

The GP30 Fully Automatic Polarimeter features an advanced LED cold light source, replacing traditional sodium and tungsten halogen lamps for longer lifespan and stable performance. It supports multiple measurement modes, including optical rotation, specific rotation, concentration, and sugar content, offering versatility for various industries. Equipped with built-in Peltier temperature control, the instrument ensures accurate and stable results by maintaining precise temperature conditions. Additionally, it includes user management and real-time data printing functions, making it easy to store, manage, and share results. Ideal for pharmaceutical, food, and chemical industries, the GP30 guarantees high precision and reliability.

1: LED cold light source replaces traditional sodium and tungsten halogen lamps;

2: Can be used for measuring optical rotation, specific rotation, concentration, and sugar content;

3: Equipped with user management and data printing functions

Adopting visual aiming and manual measurement methods, it is easy to use.

Adopting photoelectric detection and automatic servo mechanism control, digital display reading, capable of measuring dark samples; It can also measure sugar content and is equipped with an RS232 interface, which can transmit data to a PC.

1.The control unit adopts a 16 bit microprocessor chip, which makes the computer faster and has good real-time performance.

2.Digital temperature control regulation has been achieved, allowing for arbitrary setting of starting temperature and selection of different linear heating rates.

3.Enhanced anti-interference capability through digital filtering technology.

4.It can automatically record the initial and final melting temperatures.

1: Test mode: melting point, boiling point, sliding point;

2: Treat 4 samples at a time;

3: HD video instead of the traditional microscope, high visual inspection;

4: Automatic recording of melting process, initial melting, final melting;

1: Automatic integration to realize one-button measurement function;

2: Treat 4 samples at a time;

3: HD video instead of the traditional microscope, high visual inspection;

4: Automatic recording of melting process, initial melting, final melting;

1: Automatic integration to realize one-button measurement function;

2: Treat 4 samples at a time;

3: HD video instead of the traditional microscope, high visual inspection;

4: Automatic recording of melting process, initial melting, final melting;

1: Automatic integration to realize one-button measurement function;

2: Treat 4 samples at a time;

3: HD video instead of the traditional microscope, high visual inspection;

4: Comply with 21CFR Part 11, audit tracking, pharmacopoeia and electronic signature;

The GM70 Fully Automatic Melting Point Apparatus combines advanced technology with ease of use, offering a seamless testing experience. It features automatic integration for one-button measurements, allowing you to test 4 samples simultaneously. The HD video recording of the melting process, including initial and final melting points, replaces traditional microscopes, providing high-quality visual inspection. With automatic data recording and tamper-proof data preservation, it ensures reliable and secure results. Ideal for industries such as pharmaceuticals and chemicals, the GM70 simplifies your testing process while meeting regulatory compliance standards, making it the perfect choice for high-precision testing needs.

1.4-channel fluid-addition module, standard 40 stations.

2.Four liquid adding module units, burettes and pipelines all can be acid-proof, alkali-proof and corrosion resistance.

3.Imported corrosion-resistant PTFE rotating valve, PTFE corrosion-resistant burette, high-power mixing table, using the coil to achieve magnetic mixing.

4.High-precision closed-loop control, ensuring accurate titrating.

1.4-channel fluid-addition module, standard 16 stations, optional 20/34/40 stations rotary type automatic sampler can be added.

2.Four liquid adding module units, burettes and pipelines all can be acid-proof, alkali-proof and corrosion resistance.

3.Imported corrosion-resistant PTFE rotating valve, PTFE corrosion-resistant burette, high-power mixing table, using the coil to achieve magnetic mixing.

4.High-precision closed-loop control, ensuring accurate titrating.

1.Imported solenoid valve, PTFE corrosion resistance burette, high-power mixing table, using the coil to achieve magnetic mixing;

2.High-precision closed-loop control, ensuring accurate titration;

3.High-precision titration buret is accurate to 0.003mm;

4.The whole pipeline is fully sealed design, fast and convenient replacement;

1.2-channel fluid-addition module, standard 16 stations, optional 20/34/40 stations rotary type automatic sampler can be added.

2.Two liquid adding module units, burettes and pipelines all can be acid-proof, alkali-proof and corrosion resistance.

3.Imported corrosion-resistant PTFE rotating valve, PTFE corrosion-resistant burette, high-power mixing table, using the coil to achieve magnetic mixing.

4.High-precision closed-loop control, ensuring accurate titrating.

1.Single fluid-addition module. Optional 16/20/34/40 stations rotary type automatic sampler can be added.

2.The driven liquid adding module unit, burette and pipelines all can be acid-proof, alkali-proof and corrosion resistance.

3.Imported corrosion-resistant PTFE rotating valve, PTFE corrosion-resistant burette, high-power mixing table, using the coil to achieve magnetic mixing.

4.High-precision closed-loop control, ensuring accurate titrating.

1.4-channel fluid-addition module, standard 34 stations.

2.Four liquid adding module units, burettes and pipelines all can be acid-proof, alkali-proof and corrosion resistance.

3.Imported corrosion-resistant PTFE rotating valve, PTFE corrosion-resistant burette, high-power mixing table, using the coil to achieve magnetic mixing.

4.High-precision closed-loop control, ensuring accurate titrating.

The GZ608-ST Automatic Sampling Dissolution Apparatus is designed for precise and efficient dissolution testing of sustained-release tablets. It features a coated dissolution cup with automatic center positioning and can store at least 200 experimental methods. The software includes permission management, audit tracking, and supports up to 100 preset login accounts with hierarchical authority levels. With an integrated database, it securely stores records for up to 10 years. The system also offers automatic solvent replacement during testing, ensuring accuracy. An integrated shading and dustproof cover effectively prevents sample photodegradation, making the system more convenient and easy to use.

To determine the drop points and softening points of noncrystallographic polymer compounds, to determine their concentration density, polymerization degree, heat resistance and other physical and chemical characteristics;

1. Coated dissolution cup, automatic center positioning.

2. At least storing 300 experimental methods, the software has authority management and audit tracking functions.

3. It can store at least 300 preset login accounts and passwords, operating authority grading management.

4. At least 3 authority levels can be assigned; the details of each authority level can be customized by the customer based on their own risk assessment.

The GV20K Karl Fischer Coulomb moisture analyzer adopts a 5.7-inch capacitor high-definition color touch screen, which is effortless and easy to operate like a mobile phone. The operation interface is simple and intuitive, and the navigation based operation mode reduces learning costs and makes it faster to get started.

The pH meter is a commonly used instrument, mainly used to accurately measure the pH value of liquids. It is widely used in water environment testing, industry, electric power, agriculture, medicine, food, scientific research and environmental protection and other fields.

The viscosity temperature control integrated machine integrates viscosity measurement and precise temperature control. Breaking through the existing market of using a constant temperature water bath, viscosity measuring instrument, and small sample adapter to form a split machine.

The ZG-DSC-80L Fully Automatic Differential Scanning Calorimeter offers precise thermal analysis with its dual temperature probes, ensuring high repeatability in sample temperature measurements. Featuring a digital gas mass flowmeter that automatically switches between two gas flow rates for fast transitions and minimal stability time, it guarantees accurate and reliable results. The instrument includes a standard sample for easy temperature coefficient corrections and comes equipped with an automatic calibration function, streamlining operations. Ideal for industries like automotive, aerospace, and renewable energy, the ZG-DSC-80L delivers superior performance for diverse thermal analysis needs.

Dual beam optical path can effectively suppress the drift of circuit optical path, suitable for long-term testing

Automatic wavelength calibration, automatic dark current and blank correction, automatic switching of light source and filter

Spacious sample compartment, capable of accommodating 5-100mm cuvettes, supporting various accessory parts required for testing

The GR series fully automatic refractometer is equipped with high-performance linear CCD photosensitive components, and is equipped with a semiconductor Peltier super temperature control system through high-speed and high-precision signal acquisition and analysis processing technology.

GR15 visual discrimination reading scale. It can efficiently and accurately measure the refractive index (nD) of various liquids such as transparent, semi transparent, dark, and viscous, as well as the mass fraction (Brix) of sugar solutions.