- Home

- Hot Sales

- Products

- Application

- About Us

- Support

- News

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

Have you ever wondered how scientists determine the purity of a compound? A melting point apparatus is key to this process. This tool is essential in scientific research and industry, providing precise measurements of melting points. In this post, you'll learn about different types of melting point apparatus, their workings, and their applications across various fields.

A melting point apparatus is a scientific device used to determine the melting point of a solid substance. The melting point is the temperature at which a solid changes into a liquid. This characteristic helps identify and assess the purity of a compound. By knowing the melting point, scientists and technicians can verify if a substance is what it claims to be or if impurities are present.

The main purpose of a melting point apparatus is to provide accurate and reliable measurements of melting points. This information is crucial in many fields such as pharmaceuticals, chemistry, and materials science. It helps ensure quality control, supports research, and aids in product development. The apparatus makes the melting point determination process easier, faster, and more consistent than manual methods.

There are several types of melting point apparatus available, each suited to different needs and levels of precision:

● Manual Melting Point Apparatus: This basic type requires the user to observe the sample as it heats and note the temperature at which melting occurs. It is simple and affordable but requires skill and attention.

● Automatic Melting Point Meter: This advanced device heats the sample automatically and records the melting point digitally. It reduces human error and increases accuracy. Many models also offer data storage and analysis features.

● Slip Melting Point Instrument: Designed for specific substances like fats and oils, this apparatus measures the temperature at which a sample moves or "slips" inside a tube under heat. It is especially useful in food, cosmetics, and pharmaceutical industries.

Each type serves different laboratory requirements. Manual apparatus suits basic tests or educational use. Automatic meters fit high-precision labs needing fast, reliable results. Slip melting point instruments handle specialized applications.

Tip: Choose a melting point apparatus based on your sample type and required accuracy to optimize testing efficiency and reliability.

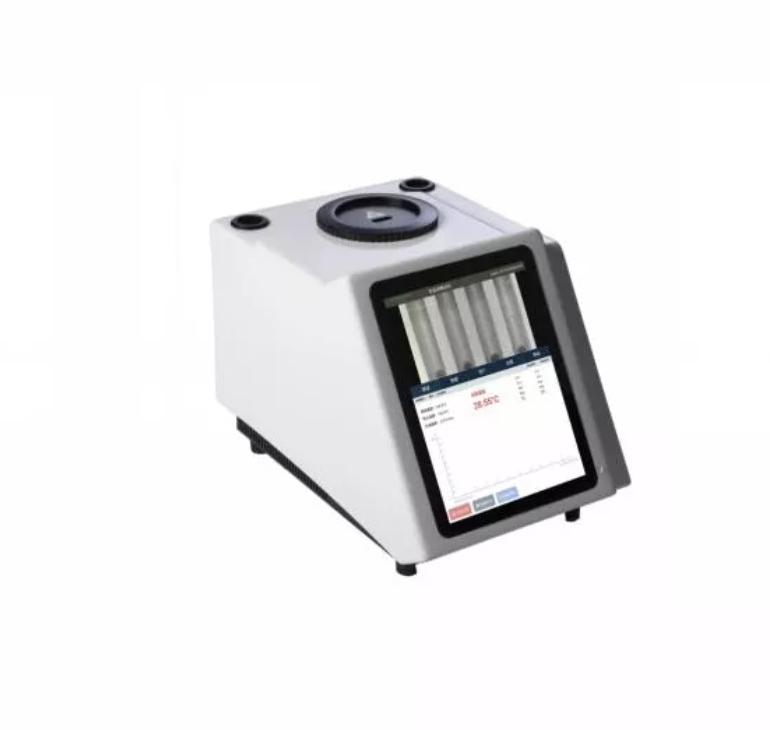

An automatic melting point meter is a modern, precise instrument designed to determine the melting point of solid substances quickly and accurately. It heats the sample gradually and records temperature changes digitally. This automated process reduces human error and improves repeatability, making it ideal for quality control and research labs.

Many automatic meters feature built-in cameras or sensors that monitor the sample visually or thermally. They capture the exact moment melting starts and ends, providing a melting point range with high accuracy. Some models allow simultaneous testing of multiple samples, increasing throughput and efficiency.

This type suits industries like pharmaceuticals, chemistry, and materials science, where precise melting point data verifies compound identity and purity. Its ease of use and digital data output simplify documentation and compliance with regulatory standards.

The slip melting point instrument specializes in measuring the temperature at which a sample moves or "slips" inside a capillary tube under heat. It is especially useful for testing fats, oils, waxes, and similar substances. This method differs from standard melting point determination by focusing on the movement of the sample rather than just its phase change.

Many slip melting point instruments operate fully automatically, combining digital image analysis and temperature control. They comply with industry standards such as AOCS Cc 3-25, UNI EN ISO 6321, and various pharmacopoeias, ensuring reliable, comparable results.

These instruments often include software for data management, user access control, and result archiving. They serve industries like food, cosmetics, and pharmaceuticals, where slip melting characteristics influence product quality and performance.

The manual melting point apparatus represents the traditional method for melting point determination. It usually consists of a heating block or oil bath and a magnifying lens or microscope to observe the sample in a capillary tube. The operator manually heats the sample and watches for the melting point, noting the temperature from an attached thermometer.

While manual apparatuses are cost-effective and straightforward, they demand skill and attention to detail. The risk of human error is higher, and measurements can vary between users. Despite this, manual methods remain popular in educational settings and small labs where budget constraints exist or automation is unnecessary.

Manual devices are portable and simple to maintain, making them practical for quick checks or field use. However, they lack the speed, precision, and data management features of automatic systems.

Tip: Select a melting point apparatus that matches your sample type and testing needs—automatic meters for precision, slip instruments for fats and oils, and manual devices for basic or educational use.

A melting point apparatus works by gradually heating a solid sample and observing the temperature at which it changes from solid to liquid. This temperature is the melting point, a key property for identifying substances and checking purity.

Most melting point apparatuses use a small glass capillary tube filled with the sample. The tube is placed inside the device, where it is heated evenly. A thermometer or digital sensor measures the temperature as it rises. The apparatus detects the start and end of melting by visual observation or automated sensors.

In manual devices, a user watches the sample through a magnifying lens and notes the temperature when melting begins and finishes. Automatic meters use cameras or optical sensors to detect melting precisely and record the data digitally.

Slip melting point instruments measure the temperature at which the sample moves or "slips" inside the tube under heat, useful for fats and oils. This method relies on visual detection of movement rather than just phase change.

Finely grind the sample using a mortar and pestle and ensure it is completely dry.

Pack the powder into a clean, dry capillary tube (approximately 100 mm long).

Drop the tube vertically onto a hard surface several times (about 8 times) to compact the sample at the bottom to a height of about 3–5 mm.

Place the prepared capillary tube into the melting point apparatus.

Ensure the furnace or chamber is empty before testing. For automatic testing, make sure the camera or sensor can clearly observe the sample.

Turn on the instrument and allow it to preheat for about 20 minutes to stabilize the internal temperature.

Enter or confirm the test parameters on the instrument interface:

● Sample name

● Start temperature: typically 5–7°C below the expected melting point

● Heating rate: usually 1°C/min

● Stop temperature: several degrees above the expected melting point

● Once the temperature stabilizes at the starting point (indicated by a beep), insert the sample tube.

● After reinsertion, wait until the temperature stabilizes again before pressing the “Start Heating” or “Ramp” button.

● The instrument will heat the sample gradually.

Manual Mode:

Observe the sample visually through the viewing window or camera.

Press “Initial Melt” when melting begins and “Final Melt” when the sample is completely liquefied.

Automatic Mode:

The system automatically detects and records the initial and final melting points through visual or optical sensors.

After the measurement:

● Review the displayed initial and final melting temperatures.

● Press “Save” to store data or “Print” to generate a report.

● For repeat tests with the same sample, you can start again from the heating step.

● To change the sample, return to the main interface and update the parameters.

Regular calibration ensures accuracy:

● Use standard reference samples (e.g., Naphthalene – 80.6°C, Adipic acid – 153°C, Anthraquinone – 217.1°C).

● Perform calibration using automatic or manual mode, with a heating rate of 1°C/min.

● If the measured melting point deviates or the melting range is less than 5°C, adjust the starting temperature to at least 5°C below the final melting point and recalibrate.

● Up to three calibration points (0–100°C, 100–200°C, 200–400°C) may be set; the last calibration in each range is considered valid.

After measurement, remove and discard used capillary tubes or clean them thoroughly.

Ensure the heating chamber is free from residue before the next test.

If calibration errors occur, restore factory settings to recover original parameters.

Use dry, finely ground, and well-packed samples.

Maintain a slow and uniform heating rate (around 1°C/min) for precise and reproducible melting point determinations.

In the pharmaceutical industry, melting point apparatus plays a vital role in ensuring drug quality and safety. The melting point helps identify active pharmaceutical ingredients (APIs) and excipients, confirming their identity and purity. Accurate melting point data ensures consistency between batches, which is crucial for regulatory compliance and patient safety.

Pharmaceutical companies use melting point measurements during drug development, formulation, and quality control. For example, detecting impurities or polymorphic forms of a drug can influence its efficacy and stability. Melting point apparatus provides quick, reliable results that help avoid costly errors and product recalls.

Chemical researchers rely on melting point apparatus to characterize new compounds and verify their synthesis. The melting point is a fundamental physical property that aids in identifying unknown substances and confirming chemical structures.

In organic chemistry, determining melting points helps assess purity. Impurities usually lower and broaden melting ranges, signaling the need for further purification. Researchers also use melting point data to study polymorphism, phase transitions, and reaction completeness.

Melting point apparatus supports routine lab work and advanced research by offering precise measurements. It accelerates the process of compound validation, saving time and resources.

Material scientists use melting point apparatus to evaluate properties of metals, polymers, ceramics, and composites. Knowing melting points helps in selecting materials for manufacturing processes and product design.

For example, polymers with specific melting points are chosen for thermal stability in electronics or packaging. Metals require melting point data for casting, welding, and alloy development. Melting point measurements also detect contamination or degradation in materials.

In research and development, melting point apparatus aids in discovering new materials with tailored thermal properties. It ensures materials meet industry standards and perform reliably under expected conditions.

Tip: Use melting point apparatus early in product development to identify impurities and ensure material consistency, reducing costly failures later.

Automatic melting point meters deliver highly precise and accurate melting point measurements. They use digital sensors and cameras to detect the exact temperature when a sample starts and finishes melting. This reduces human error common in manual observations. The consistent heating rate and advanced detection methods ensure reliable results every time. This precision is crucial in industries like pharmaceuticals, where even slight deviations can affect product quality and safety.

These devices simplify the melting point determination process. They automatically heat samples at controlled rates, monitor melting visually or thermally, and record data digitally. Users don’t need to watch samples constantly or manually note temperatures. Many models allow testing multiple samples simultaneously, speeding up lab workflows. The user-friendly interfaces and software reduce training time and increase productivity, helping labs handle higher sample volumes with less effort.

Automatic melting point meters often come with features ensuring compliance with regulatory and industry standards. They support standardized testing protocols, data integrity, and traceability. Digital records and software management help labs meet requirements from agencies like the FDA or pharmacopoeias worldwide. Some instruments include user access controls and calibration verification, enhancing quality assurance. This compliance is vital for labs needing certified results for product approval or research validation.

Tip: Choose an automatic melting point meter that offers digital data management and compliance features to streamline lab workflows and meet regulatory demands efficiently.

Choosing the right melting point apparatus starts with understanding your sample. Different instruments suit different sample sizes and types. For example, if you work with tiny amounts of powder, an automatic melting point meter that requires minimal sample volume is ideal. It ensures precise heating and measurement without wasting material.

If your samples include fats, oils, or waxes, a slip melting point instrument is more appropriate. This device measures the temperature at which the sample moves or slips inside a tube, a method better suited for these substances. Manual apparatuses work well for simple solids and educational purposes but need more sample and user skill.

Always consider the physical form of your sample—powder, crystalline solid, or semi-solid. This affects how you prepare the sample for testing and which apparatus will handle it best. Using the wrong apparatus can lead to inaccurate results or damage to the sample.

Another key factor is the temperature range the apparatus can measure. Some devices cover a broad range, from below room temperature to over 300°C, while others are limited to narrower ranges. Choose an apparatus that comfortably covers your expected melting points.

Accuracy is critical, especially in research and quality control. Automatic melting point meters typically offer high precision, often within ±0.1°C, thanks to digital sensors and controlled heating. Manual devices may have larger error margins due to human observation and less precise temperature control.

Consider the heating rate too. Slower, controlled heating yields more accurate results, especially for substances with close melting points or polymorphs. Many automatic instruments allow you to set heating rates precisely, improving repeatability.

Budget plays a role in choosing a melting point apparatus. Manual devices are generally less expensive and easier to maintain but require more operator skill and time. Automatic meters cost more upfront but save labor costs and reduce errors over time.

Maintenance should not be overlooked. Automatic instruments may need regular calibration, software updates, and occasional repairs. Check if the manufacturer offers support, training, and spare parts. Slip melting point instruments often require specialized capillaries and cleaning routines.

Consider your lab’s workload and staff expertise. Investing in a reliable, easy-to-maintain apparatus can reduce downtime and increase productivity. Balancing cost with features and support ensures you get the best value.

Tip: Match your melting point apparatus to your sample type, required accuracy, and budget to optimize lab efficiency and ensure reliable results.

A melting point apparatus is essential for determining the melting point of solid substances, aiding in purity assessment. Various types, including manual, automatic, and slip instruments, cater to different needs. Automatic meters offer precision and efficiency, while manual devices are cost-effective. These tools are vital in industries like pharmaceuticals and materials science. Shanghai Zhuoguang Instrument Technology Co. Ltd. provides advanced melting point meters, ensuring accurate and reliable results, enhancing research and quality control processes.

A: A Melting Point Apparatus is a scientific device used to determine the temperature at which a solid turns into a liquid, crucial for identifying and assessing compound purity.

A: An Automatic Melting Point Meter gradually heats a sample and uses digital sensors to record the melting point, reducing human error and improving accuracy.

A: A Slip Melting Point Instrument is ideal for testing fats and oils, measuring the temperature at which a sample moves inside a tube.

A: Costs vary; manual devices are affordable, while automatic meters are pricier but offer advanced features and precision.

A: Benefits include accurate melting point determination, improved quality control, and reliable data for research and development.