- Application Cases

- Hot Sales

- Products

- Application

- About Us

- Support

- News

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-12-04 Origin: Site

Residual alkalinity, a common by-product or key component in industries such as chemical manufacturing, textile processing, and water treatment, primarily consists of sodium hydroxide (NaOH) and sodium carbonate (Na₂CO₃). Its content directly affects product quality, process stability, and environmental compliance—for example, excessive residual alkalinity in textile wastewater may cause equipment corrosion, while inaccurate control in chemical synthesis can lead to reaction inefficiency or product defects. Traditional titration methods often suffer from manual operation errors, ambiguous endpoint judgment, and long analysis cycles, making it challenging to meet the demand for high-precision and rapid detection in modern industrial production.

Residual alkalinity, mainly composed of sodium hydroxide and sodium carbonate, is a key indicator in many industrial production processes. Its accurate content determination is crucial for quality control, process optimization, and product performance guarantee. The GT80 Fully Automatic Potential Titrator, with its high precision, efficiency, and automation, provides a reliable solution for the determination of residual alkalinity. This article details two practical application cases of the GT80 Fully Automatic Potential Titrator in residual alkalinity analysis, aiming to provide reference for relevant industry practitioners.

The determination system is composed of professional equipment to ensure the accuracy and stability of test results:

GT80 Fully Automatic Potential Titrator: The core equipment for titration, with high-precision liquid delivery and real-time potential monitoring functions.

pH composite electrode: Responsible for detecting potential changes in the solution during the titration process to accurately identify the endpoint.

100mL titration cup: Provides a suitable reaction space for the sample and titrant.

Electronic balance (accuracy to 0.1mg): Used for precise weighing of samples to ensure the accuracy of dosage.

Auxiliary equipment: Beakers, measuring cylinders, volumetric flasks, etc., for sample preparation and solution configuration.

Titrant: 0.01mol/L HCl solution (standard titrant with stable concentration)

Sample: Residual alkalinity (provided by the customer, pH=12.3, sample number: 22102801)

Solvent: Ethanol (used to dissolve the sample to form a homogeneous titration system)

Sample Preparation: Weigh an appropriate amount of residual alkalinity sample, dissolve it in 50mL of ethanol, and stir thoroughly to ensure complete dissolution.

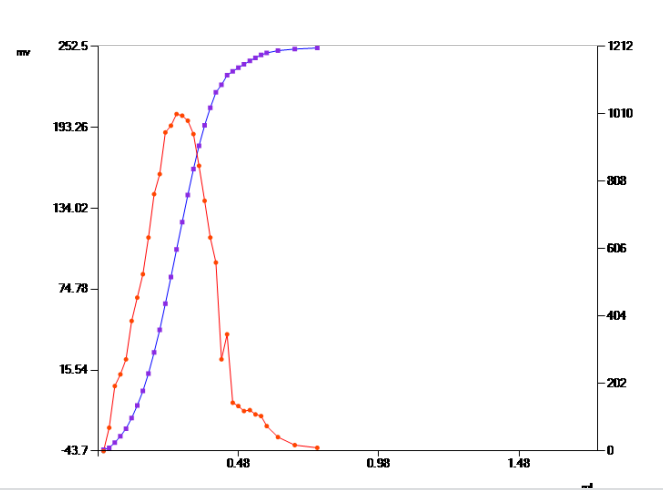

Titration Operation: Adopt the potentiometric titration method, use 0.01mol/L HCl solution as the titrant to titrate the sample solution, and record the titration volume in real-time.

Blank Experiment: Conduct a blank titration experiment under the same conditions to eliminate the influence of solvent and reagents on the test results.

Calculation Formula:

X = (V1 - V0) * C0 * 0.106 / m * 100

Where:

X: Mass percentage content of sodium hydroxide in the residual alkalinity (%)

V1: Titration volume of the sample solution (mL)

V0: Titration volume of the blank experiment (mL)

C0: Concentration of the titrant (mol/L)

0.106: Molar mass of sodium hydroxide Molar mass of sodium hydroxide after conversion (kg/mol)

m: Mass of the sample (g)

Leveraging the GT80’s automatic titration and endpoint recognition capabilities, the test was carried out under the conditions of 25℃ environment temperature and 52% relative humidity. Three parallel experiments were conducted to verify the repeatability of the instrument—an essential requirement for industrial quality control.

The test was carried out under the conditions of 25℃ environment temperature and 52% relative humidity, and three parallel experiments were conducted to ensure the reliability of the results:

| Determination Sequence | Sample Injection Amount (g) | Endpoint Volume (mL) | Content Result (%) |

|---|---|---|---|

| 1 | 0.4725 | 7.164 | 1.55 |

| 2 | 0.4832 | 7.119 | 1.50 |

| 3 | 0.4955 | 7.458 | 1.54 |

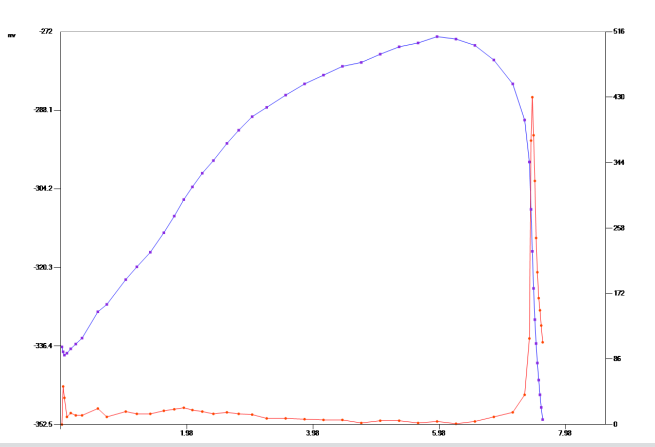

The average content of sodium hydroxide in the residual alkalinity was calculated as 1.53%, and the entire analysis process took only about 5 minutes, showing high efficiency. The relative deviation between parallel samples was less than 0.3%, which fully meets the precision requirements of industrial standard methods, reflecting the GT80’s ability to minimize human error through automated operation. The following are Case 1, 2, and 3 in order.

Consistent with Case 1, the same set of professional testing equipment is adopted to maintain the consistency and comparability of the test system:

GT80 Fully Automatic Potential Titrator

pH composite electrode

100mL titration cup

Electronic balance (accuracy to 0.1mg)

Auxiliary equipment: Beakers, measuring cylinders, volumetric flasks, etc.

Titrant: 0.1003mol/L HCl solution (standardized titrant with accurate concentration)

Sample: Residual alkalinity (provided by the customer, sample number: 22102501)

Solvent: Ethylene glycol (has good solubility for the sample, ensuring the smooth progress of the titration reaction)

Sample Preparation: Weigh a proper amount of residual alkalinity sample, dissolve it in 50mL of ethylene glycol, and stir fully to form a uniform solution.

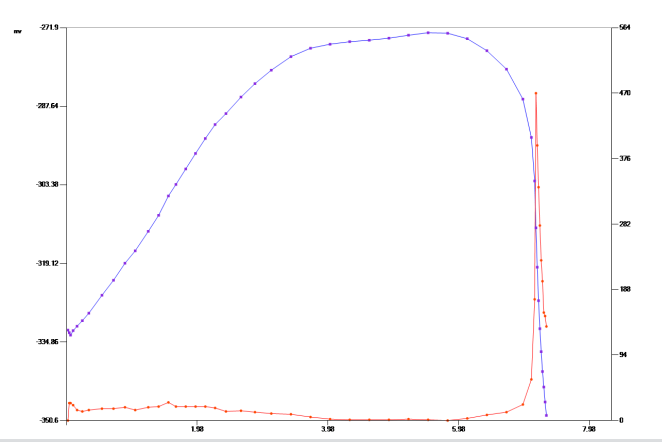

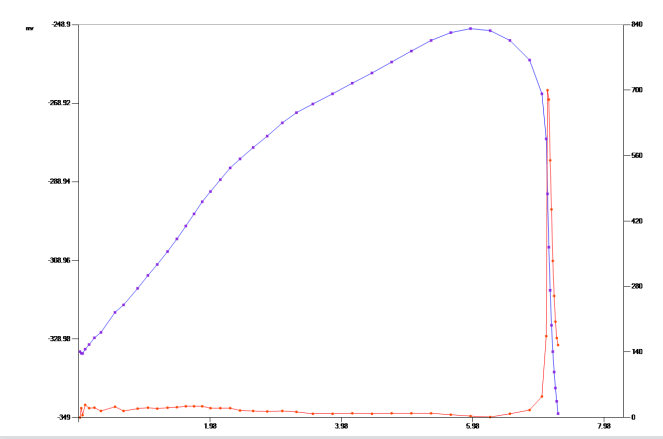

Titration Operation: Perform potentiometric titration on the sample solution with 0.1003mol/L HCl solution as the titrant, and accurately record the titration volume when the endpoint is reached.

Calculation Formula:

X = (V1 - V0) * C0 * 105.99 * 100 / (m * 1000 * 2)

Where:

X: Mass percentage content of sodium carbonate in the residual alkalinity (%)

V1: Titration volume of the sample solution (mL)

V0: Titration volume of the blank experiment (mL)

C0: Concentration of the titrant (mol/L)

105.99: Molar mass of sodium carbonate (g/mol)

m: Mass of the sample (g)

For samples with higher alkalinity content, ethylene glycol was selected as the solvent to enhance sample solubility. The GT80’s flexible adaptability to different solvents and titrant concentrations allowed for seamless method adjustment without modifying core hardware, demonstrating its versatility in complex sample matrices.

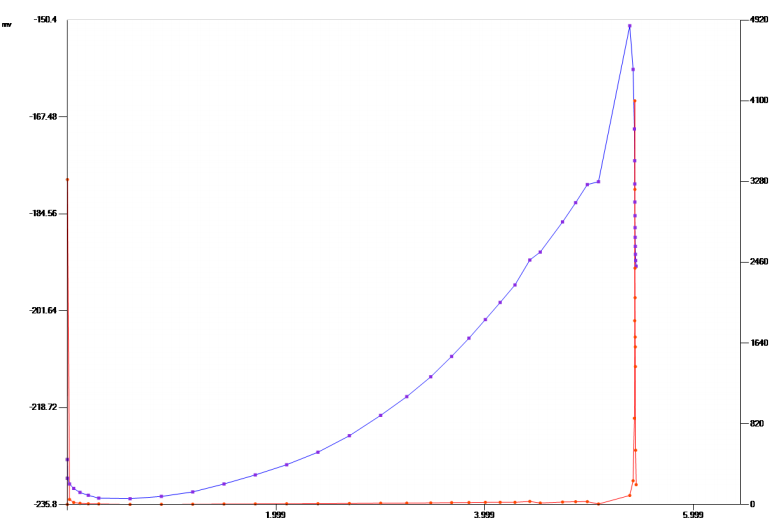

Under the environmental conditions of 25℃ and 52% relative humidity, three parallel tests were conducted, and the results are as follows:

| Determination Sequence | Sample Injection Amount (g) | Endpoint Volume (mL) | Content Result (%) |

|---|---|---|---|

| 1 | 0.3284 | 5.437 | 8.80 |

| 2 | 0.3521 | 5.836 | 8.81 |

| 3 | 0.4088 | 6.760 | 8.79 |

The average content of sodium carbonate in the residual alkalinity was 8.80%, and the analysis time of each sample was about 5 minutes, which effectively improved the testing efficiency. Notably, the GT80’s built-in data calculation function automatically processed the titration volume and sample mass, eliminating manual calculation errors and enabling direct output of content results—greatly simplifying the workflow for laboratory technicians.

In industrial testing scenarios where accuracy, efficiency, and repeatability are critical, the GT80 Fully Automatic Potential Titrator stands out as a superior alternative to traditional manual titration. Its integration of automatic sample delivery, real-time potential monitoring, and intelligent endpoint judgment addresses the core pain points of conventional methods, while its compatibility with different solvents and sample matrices expands its application scope across multiple industries.

The two sets of experimental data show that the GT80 Fully Automatic Potential Titrator has the advantages of high accuracy, good repeatability, and fast analysis speed in the determination of residual alkalinity. Whether using ethanol or ethylene glycol as the solvent, it can stably and reliably obtain the content of sodium carbonate in the residual alkalinity. The instrument's automatic operation reduces human errors, and the precise potential monitoring ensures the accuracy of the titration endpoint. It is an ideal choice for residual alkalinity analysis in industrial production, scientific research, and other fields. For more details about the GT80 Fully Automatic Potential Titrator, please visit the official website: https://www.zhuoguanginstrument.com/GT80-Fully-Automatic-Potential-Titrator-with-Automatic-Sampler-for-Mass-Determination-pd517976658.html.