- Home

- Hot Sales

- Products

- Application

- About Us

- Support

- News

- Contact

Views: 0 Author: Site Editor Publish Time: 2026-01-16 Origin: Site

Soy sauce is a staple ingredient in various cuisines around the world, and its quality is influenced by several factors, including its amino acid nitrogen content. The higher the amino acid nitrogen (also known as free amino nitrogen), the richer the soy sauce's umami flavor. As such, determining this content is vital for ensuring the product meets the required standards for quality and safety. One of the most effective and reliable methods for measuring this content is potentiometric titration.

In this article, we will discuss how the GT70 Automatic Titrator and the potentiometric titration method can be used to measure amino acid nitrogen in soy sauce. We will explore the process, advantages, and results of this method, while also highlighting the importance of accurate analysis for ensuring the high quality of soy sauce production.

Amino acid nitrogen is a crucial parameter in determining the quality of soy sauce. It represents the nitrogen content in free amino acids, which are released from the hydrolysis of proteins during the fermentation process. This nitrogen contributes to the characteristic savory taste (umami) of soy sauce, and its concentration directly correlates with the flavor strength and overall quality of the product.

For soy sauce manufacturers, it is important to monitor amino acid nitrogen content to ensure product consistency and compliance with food safety standards. The GB/T 5009.235-2016 national food safety standard for amino acid nitrogen in food provides clear guidelines on how to determine this value, with potentiometric titration being one of the most accurate methods.

The potentiometric titration method involves measuring the potential change of a sample solution as a titrant is added. This technique is highly suitable for determining the amino acid nitrogen content in soy sauce because it allows precise measurement of endpoint determination based on the change in pH during titration.

To perform potentiometric titration, the following equipment and reagents are typically required:

GT70 Automatic Titrator: This instrument automates the titration process, offering high precision and minimizing human error.

pH Composite Electrode: Used to measure the pH changes during the titration.

Sodium Hydroxide Solution (0.05 mol/L): Used as the titrant for neutralizing the amino acids in the sample.

Formaldehyde Solution: Added to react with amino acids and promote the titration process.

Sample of Soy Sauce: The solution being tested.

Sample Preparation: Accurately pipette 5 mL of soy sauce into a 100 mL volumetric flask, rinse the pipette and combine the rinse with the sample. Then, fill the flask to the 100 mL mark with distilled water.

Dilution: Take 20 mL of the diluted solution and add 60 mL of water. Stir the mixture thoroughly.

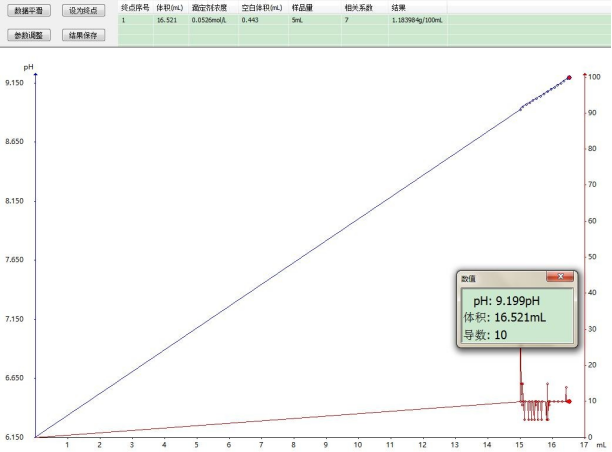

Titration: The sample is titrated using sodium hydroxide solution (0.05 mol/L) to a pH endpoint of 8.2. Afterward, 10 mL of formaldehyde solution is added, and the titration continues until the pH reaches 9.2.

Blank Test: A blank test is also conducted to subtract the volume of titrant used in the absence of amino acids, ensuring accuracy.

The titration process is controlled by the following parameters:

Titration Mode: Endpoint titration.

Minimum Titrant Addition: 0.02 mL.

Electrode Balance Time: 4 seconds.

Pre-stirring Time: 10 seconds.

Electrode Balance Potential: 1 mV.

Titration Speed: Standard.

End Volume: 20 mL.

First Endpoint pH: 8.2.

Second Endpoint pH: 9.2.

Once the titration is complete, the amino acid nitrogen content (X) in the soy sauce sample can be calculated using the following formula:

X=(V1−V0)×C×0.014×100V×20X = \frac{{(V1 - V0) \times C \times 0.014 \times 100}}{{V \times 20}}X=V×20(V1−V0)×C×0.014×100

Where:

X is the amino acid nitrogen content (g/100 mL).

V1 is the volume of sodium hydroxide used for the sample after adding formaldehyde (mL).

V0 is the volume of sodium hydroxide used for the blank test (mL).

C is the concentration of the sodium hydroxide solution (mol/L).

V is the volume of the soy sauce sample (mL).

The potentiometric titration method offers several benefits, particularly in the context of analyzing amino acid nitrogen content in soy sauce.

The GT70 Automatic Titrator ensures precise control of the titration process. By automating key steps, it reduces human error, improves reproducibility, and ensures accurate results, which is crucial for quality control in soy sauce production.

With the GT70's user-friendly interface, the titration process becomes simpler and more efficient. The operator can set up and monitor the titration process with ease, while the system automatically calculates the endpoint and records the results.

Automating the titration process significantly reduces analysis time compared to manual methods. The GT70 Titrator provides fast, reliable results, which is especially beneficial for large-scale production environments where efficiency is key.

Using potentiometric titration to measure amino acid nitrogen content ensures that soy sauce manufacturers comply with the relevant food safety standards, such as GB/T 5009.235-2016, which specifies the method for measuring amino acid nitrogen in food products.

An example of the results from a titration test of different soy sauce brands is shown below:

| Brand | Sample Volume (mL) | Titrant Volume (mL) | Amino Acid Nitrogen (g/100mL) |

|---|---|---|---|

| Good Wife | 5 | 7.683 | 0.53 |

| Dexin Zhai | 10 | 10.098 | 0.71 |

| Weida Mei | 16.459 | 16.521 | 1.2 |

As shown, the results demonstrate the effectiveness of potentiometric titration for accurately determining the amino acid nitrogen content in soy sauce, with high repeatability and compliance with national standards.

The GT70 Automatic Titrator provides an efficient, reliable, and precise solution for measuring amino acid nitrogen in soy sauce. By automating the potentiometric titration process, it ensures high-quality results, reduces human error, and enhances the overall efficiency of the testing procedure. This method not only complies with industry standards but also ensures that soy sauce manufacturers can produce products with consistent quality and flavor.

In the competitive world of soy sauce production, ensuring the highest quality through precise testing methods is crucial. The GT70 Titrator plays an essential role in this process, delivering accuracy and reliability every time.